The machining centre

is a machine tool which is capable of doing multiple machining operations on a

work part in a single setup. Recent CNC machining centers are equipped with lot

of feature which can increase the production and time saving. Time saving on

CNC is a huge profit for the company.

The machining center designation refers to the orientation

of the machine spindle, and is classified as below:

- Vertical Machining centers (VMC).

- Horizontal Machining centers (HMC).

- Universal Machining centers (UMC).

- Vertical machining centre (VMC):

These machines

have its spindle on a vertical axis relative to the work table and always

perpendicular to the machining bed. A vertical machining centre (VMC) is

typically used for flat work that requires tool access from top. E.g. mould and

die cavities, large components of aircraft. Vertical machining centers are

limited for the small type of components. These machines are less expensive

compared to the other machining centers.

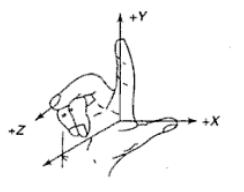

Axes Designation in vertical machining

centers is as shown below:

2. Horizontal machining centre (HMC):

This type of

machines have the Z axis in the horizontal position and the part is loaded on

the table vertically in X and Y direction. Horizontal machining centers are used

for machining the cube shaped parts where tool access can be best achieved on

the sides of the cube. The number of setups can be reduced compared to the

Vertical machining centers. Some

horizontal machining centers have their bed in X and Y axis perpendicular to

the spindle and some have in X and Z axis parallel to the spindle.

Axes Designation in vertical machining

centers is as shown below:

3. Universal machining centre (UMC):

These machines are

the machines which has 5 or more axis. It has a work head that swivels its

spindle axis to any angle between horizontal and vertical making this a very

flexible machine tool. The complex parts

like Aerofoil shapes, curvilinear geometries can be machined using these

universal machining centers. These machines works on the swivels spindle axis

which is called pivot point. Most of these machines are used for finishing of

parts due to achieving of high accuracy.

Advantages of machining centers:

·

Reduced setups which gains the time and saves

the machining cost.

·

Reduced part handling by the operator, due to

reduced setups.

·

The parts utilize the same fixture throughout

their processing which Increases the accuracy and repeatability.

·

Faster process and faster delivery of parts in

small lot sizes.

Disadvantages of machining centers:

·

These machines are more expensive compared to other

conventional machines.

·

Need highly skilled and trained labors to

operate these machines.

·

Needs software’s for DNC, Simulation and CAM

programming, which makes the cost higher to use these machines.

Features of CNC machining centers:

Usually the CNC machining centers are designed with many features

to reduce non productive time. Some of the features are:

1.

Automatic tool changer (ATC).

2.

Automatic work part positioned.

3.

Automatic pallet changer.

1. Automatic tool changer (ATC):

The Cutting tools are stored in the storage

unit called the “tool magazine” which is integrated with the machine tool and

named with the tool numbers. When a tool number is called by the tool number

the magazine rotates to the proper position and an automatic tool changer (ATC)

with the program control, exchanges the tool in the spindle for the tool in the

tool storage unit. The Capacities of tool magazine commonly range from 16 to 80

cutting tools. These Automatic tool changes save the manual tool changing and

the big save on the cycle time or the operation time.

2. Automatic work part positioned:

Automatic work part positioning acts as

rotary axis rotating the part and give access to the cutting to machine, many

horizontal and vertical machining centers have the capability to orient the

work part relative to the spindle. The table can be oriented at any angle about

a vertical axis to permit the cutting tool to access almost the entire surface

of the part in a single setup. These automatic work part positions are

programmed by the programmer. The positioning of the rotation is very important

the tool need to move to safety plane when there is a big rotation in the

rapid. With these features we can reduce the number of setups and save huge

time and gain increase in productivity.

3. Automatic pallet changer:

Recent modern Machining centers are equipped

with two (or more) separate pallets that can be changed using an automatic

pallet changer. While machining is performed with one pallet in position at the

machine, the other pallet is in a safe location out of the machine. The

operator can unload the finished part and then fixture the raw work part for

next cycle with the pallet outside the machine. Using these automatic pallet

changers the time of loading and unloading the part can be saved and the

machine will be loaded continuously. These featured machines are very helpful in

mass production activity.

Enjoy learning CNC Programming.

I am tapping a tube with a spiral flute tap. I'm looking to try and sling the shavings off the tap after it finishes. Is there a way to program an gradually increasing RPM?

ReplyDeleteGreat work! I love the way you have present this so beautifully! keep writing!.Marvellous post by the author.

ReplyDeleteCnc machines and tools

I am very happy and relaxed too that I find this blog. I was looking for the matter discussed in blog post. If you have some more blogs on the material please share those as well. Thanks a lot and keep sharing such useful information.

ReplyDeleteglass cnc machining

Brass Pin Components

ReplyDeleteSanjayprecisiond provides cheap Brass Pin machined parts in India. Our machine parts are the finest quality and made from high-grade materials and based latest technologies.

Great post!!

ReplyDeleteThanks for sharing this post it is very informative.

Turned components manufacturers

Turned cnc parts and components manufacturers

Great post!!!

ReplyDeleteSanjay Precision Industries Provide CNC and VMC machine parts. We are manufacturers who bring in use the finest materials like Mild steel, Stainless steel grades, cast iron, investment casting, and brass & aluminum.

VMC machined Components Manufacturer

Great post...!!!I love the way that you have presented the entire concept. Thanks a lot and keep sharing such useful posts. CNC Machining Centers

ReplyDeleteI admire your unique way of writing especially the style of using the idioms and phrases which is mind-blowing. I hope you will not mind if I adopt this style of your. Many thanks.

ReplyDeleteglass cnc machining

Thank you for sharing this post...........

ReplyDeleteAce Manufacturing Systems is one of the largest CNC machine tools manufacturers and suppliers in India with expertization in manufacturing and solutions of CNC vertical and horizontal machining centers.

CNC Machine

Thanks for sharing the nice blog post...!!! check for latest Horizontal Machining Center at Acemicromatic.net

ReplyDeleteI must say that you are a wonderful blogger. Your blog simply picturize everything. I wonder if you write next post soon so that I would again have some healthy stuff to read.

ReplyDeletecnc machining service hard materials

It’s great to see good information being shared and also to see fresh, creative ideas that have never been done before.

ReplyDeletefused silica polishing service

I truly appreciate for your wonderful contribution over the same. I would like to read more from your blog site.

ReplyDeleteglass cnc machining

Your take on the subject is wonderful. I personally fully agree with your opinion. Hope to read more on this topic to increase my knowledge in this field.

ReplyDeleteprecision lapping

Thanks you for sharing this unique useful information content with us. Really awesome work. keep on blogging CNC Milling

ReplyDeleteI always like to read a quality content having accurate information regarding the subject and the same thing I found in this post. Nice work.

ReplyDeleteprecision lapping

I am interested in becoming your subscriber, so please keep me updated. I find the thoughts and opinions of this blogger, very inspiring and actually worth following. Nice work.

ReplyDeleteprecision lapping

I read your blog on daily basis. This is really great and informative post. Thanks for sharing. machined parts manufacturer

ReplyDeleteThe insights and the opinions shared in this blog are appreciable. Blogger seems like an educated and knowledgeable writer with sensible thoughts. Good work and Keep it up.

ReplyDeletesapphire substrate

Great post love the way that you have presented the entire concept. Thank you for sharing this unique useful information content with us. Awesome work.

ReplyDeleteCNC machine tools suppliers in Dubai

Accusharp Cutting Tools likes your Blog.

ReplyDeleteGreat share.

vmc and cnc job work in ahmedabad

ReplyDeleteNeptune Engineering are largest provider of VMC and CNC job work in Ahmedabad, Gujarat. And also CNC wooden pattern manufacturer and job work and pattern and die manufacturer in Ahmedabad.

The 4-axis universal machining centers G440, G640 and G840 offer our customers a heavy-duty machine series, which at the same time guarantees robust and also optimal, dynamic processes.

ReplyDelete4-axis machining centers Grob Group

The world is shifting towards more mechanized production methods; industries are competing with each other to adopt the latest advancement in technology. Similarly, the manufacturing industry is not far behind; gone are the old days of regular machining. Processes now use Computer Numerical Control (CNC) Machining.

ReplyDeleteThe manufacturing industry relies on CNC because it offers a wide range of advantages over regular machining.Full service CNC machining has proven to be highly accurate, efficient and productive in contrast to conventional machining.

Impressive written blog and valuable information shared here.

ReplyDeletePioneer Cuts

Thank you so much for sharing. Your content was very helpful. You are a marvelous writer. Good work! Polished Ceramic Substrates.

ReplyDeleteYour blog is very useful and provide tremendous facts. It is going to change the way one think by a sharp angle. Keep up the good work ahead. Thin Film Coatings .

ReplyDeletepost. I really enjoy reading and also appreciate your work. CNC machining parts This concept is a good way to enhance knowledge. Keep

ReplyDeleteI was searching for some cnc milling machine related to matter included in post. Very useful and very informative. Thanks once again and do share some more posts if you have!

ReplyDeleteCNC mould and die making machine is a newly developed CNC precision turning machine. its precise cutting process, precise machining, high speed and high precision are designed for high-end products processing, such as aircraft bodies, automobile parts and so on.

ReplyDeleteAre you looking for CNC machining Center - For heavy Industrial machining 3 axis, 4 axis, 5 Axis , Horizontal, Vertical, for more information - visit our website :

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteVery informative blog! We offer the VMC Machined Components at an affordable price. Check out our successful CNC Machined Parts with proper facilities. Check out our website for more information.

ReplyDeleteCNC Cutting Router Machine manufacture in Dubai, UAE. Dynamic CNC cut machines. Engraving Wood, Cutting Wood, Cutting & Engraving Brass.

ReplyDeleteSource: https://www.atninfo.com/uae/all/cnc-machines-315

The CNC machining centers have revolutionized the way we approach precision and efficiency in the modern world. These marvels of engineering have completely transformed the manufacturing landscape, enabling businesses to achieve unparalleled levels of accuracy, productivity, and cost-effectiveness.

ReplyDeleteCNC machining centers are true game-changers in the manufacturing industry. Their ability to combine precision, efficiency, versatility, and design capabilities has elevated the standards of production to unprecedented heights. The future of manufacturing undoubtedly lies in the hands of CNC machining centers, where limitless possibilities await those willing to harness their power.

Cnc Parts Manufacturing Lithuania

ReplyDeletecnc milling and turning Lithuania

precision cnc machining company

Cnc Milling Lithuania

This comment has been removed by the author.

ReplyDeleteI liked the way you wrote the article. It was very straightforward and your knowledge on the subject is fantastic. Glass Lapping and Polishing Services for All Materials.

ReplyDeleteThat's a great article. I got every information that i needed about cnc machine components provider. Thanks for sharing such a helpful post. Keep Posting!!

ReplyDeleteAmazing post and this is so much useful information. The precision cnc machining has many advantages and thanks for sharing this post.

ReplyDeleteGood Post

ReplyDeleteprecision cnc machining

Good post

ReplyDeleteprecision cnc machining service

This is a great overview of modern CNC machining centers and their impact on production efficiency. The integration of automation features like ATC, pallet changers, and multi-axis capabilities is transforming how precision machined components are manufactured. Reducing setups and improving repeatability not only enhances accuracy but also significantly lowers production costs—especially crucial in aerospace and high-performance industries.

ReplyDeleteThanks for sharing insights about CNC Milling.It's crucial to consider expertise, technology, and quality standards when choosing one. Each aspect plays a significant role in ensuring efficient and reliable production of plastic parts. Great information.

ReplyDeleteFMMachine offers industry-leading precision cnc machining services tailored to meet your exact specifications. Our advanced technology and skilled team ensure high-quality, accurate results for all your manufacturing needs.

ReplyDeleteFMMachine offers expert cnc manufacturing services tailored to your needs. Our advanced technology ensures precision, efficiency, and superior quality in every project.

ReplyDeleteImpressive insights! Violin Technologies seems to be setting high standards in the field of precision machined components in the USA. The commitment to quality, tight tolerances, and customized manufacturing solutions is exactly what industries need today for dependable and efficient operations. Looking forward to seeing more innovations from your team! Precision Machined Components in USA

ReplyDeleteWe are a trusted partner in the precision manufacturing industry, providing high-quality CNC machining services for critical components.

ReplyDeleteThanks for sharing such valuable insights about CNC machining. It's essential to focus on expertise, advanced technology, and strict quality standards when choosing a CNC machining service. These factors ensure efficient, precise, and reliable production of components. Great information by RPWORLD very informative and helpful!

ReplyDeleteGreat post…!!! I really appreciate the way you’ve explained the concept. It’s very informative for anyone interested in CNC machining services. Thanks a lot for sharing this and keep up the great work!

ReplyDeleteWe offer precision cnc machining service designed to meet the strictest standards of accuracy and quality. Using advanced CNC equipment and skilled technicians, we produce complex parts for aerospace, medical, automotive, and other industries.

ReplyDeleteThis blog highlights why precision machining is vital for industries that demand tight tolerances.

ReplyDeleteBest Precision Machined Components in USA.

ohio cnc machining is renowned for its creative ideas, knowledgeable staff, and sophisticated manufacturing equipment.

ReplyDeleteModern multi-axis machining centers have revolutionized custom part production. Partnering with CNC manufacturing experts helps transform complex designs into accurate, production-ready components efficiently.

ReplyDeleteLooking for reliable CNC machining services? At Northern Plastics Engg, we deliver precision-engineered components with superior quality and accuracy. Our advanced CNC technology ensures high performance, efficiency, and consistency for every project. Contact Northern Plastics Engg today for customized machining solutions that meet your exact specifications and deadlines.

ReplyDeleteAir Cooled Oil Cooler Manufacturer: Reliable Cooling Solutions for Industrial Applications

ReplyDeleteIn today’s industrial environment, maintaining the right operating temperature of hydraulic oil is critical for machine performance and longevity. This is where an Air Cooled Oil Cooler Manufacturer plays an important role by providing efficient and cost-effective cooling solutions for various industries.

What is an Air Cooled Oil Cooler?

An air cooled oil cooler is a heat exchanger designed to reduce the temperature of hydraulic oil using ambient air. Unlike water-cooled systems, air cooled oil coolers do not require an external water supply, making them easier to install, maintain, and operate. These coolers are widely used in CNC machines, hydraulic power packs, compressors, construction equipment, and other heavy machinery.

Importance of Choosing the Right Air Cooled Oil Cooler Manufacturer

Selecting a trusted Air Cooled Oil Cooler Manufacturer ensures:

Consistent cooling performance

Long equipment life

Reduced machine downtime

Lower maintenance costs

A reliable manufacturer uses high-quality raw materials, advanced manufacturing techniques, and strict quality control to deliver durable and efficient oil coolers.

Thanks for sharing insights about CNC Services for Automotive. Expertise, precision technology, and strict quality standards are essential for delivering accurate and reliable automotive components. Each factor plays a key role in achieving consistent performance and efficiency. Great information.

ReplyDeleteAir cooled oil coolers play an important role in maintaining optimal oil temperature in industrial and automotive applications Reputed air cooled oil cooler manufacturers design advanced cooling systems that use ambient air to remove excess heat without the need for water, making them cost-effective and low maintenance. These coolers are widely used in hydraulic systems, compressors, generators, construction equipment, and CNC machines.

ReplyDeleteLeading air cooled oil cooler manufacturers focus on high-quality materials, efficient fan performance, and compact designs to ensure long service life and reliable operation. Their products help prevent oil overheating, reduce equipment wear, and improve overall system efficiency. When choosing a manufacturer, it is important to consider experience, customization options, quality standards, and after-sales support. Partnering with trusted air cooled oil cooler manufacturers ensures better performance, reduced downtime, and long-term operational savings.