The machining centre

is a machine tool which is capable of doing multiple machining operations on a

work part in a single setup. Recent CNC machining centers are equipped with lot

of feature which can increase the production and time saving. Time saving on

CNC is a huge profit for the company.

The machining center designation refers to the orientation

of the machine spindle, and is classified as below:

- Vertical Machining centers (VMC).

- Horizontal Machining centers (HMC).

- Universal Machining centers (UMC).

- Vertical machining centre (VMC):

These machines

have its spindle on a vertical axis relative to the work table and always

perpendicular to the machining bed. A vertical machining centre (VMC) is

typically used for flat work that requires tool access from top. E.g. mould and

die cavities, large components of aircraft. Vertical machining centers are

limited for the small type of components. These machines are less expensive

compared to the other machining centers.

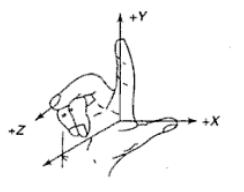

Axes Designation in vertical machining

centers is as shown below:

2. Horizontal machining centre (HMC):

This type of

machines have the Z axis in the horizontal position and the part is loaded on

the table vertically in X and Y direction. Horizontal machining centers are used

for machining the cube shaped parts where tool access can be best achieved on

the sides of the cube. The number of setups can be reduced compared to the

Vertical machining centers. Some

horizontal machining centers have their bed in X and Y axis perpendicular to

the spindle and some have in X and Z axis parallel to the spindle.

Axes Designation in vertical machining

centers is as shown below:

3. Universal machining centre (UMC):

These machines are

the machines which has 5 or more axis. It has a work head that swivels its

spindle axis to any angle between horizontal and vertical making this a very

flexible machine tool. The complex parts

like Aerofoil shapes, curvilinear geometries can be machined using these

universal machining centers. These machines works on the swivels spindle axis

which is called pivot point. Most of these machines are used for finishing of

parts due to achieving of high accuracy.

Advantages of machining centers:

·

Reduced setups which gains the time and saves

the machining cost.

·

Reduced part handling by the operator, due to

reduced setups.

·

The parts utilize the same fixture throughout

their processing which Increases the accuracy and repeatability.

·

Faster process and faster delivery of parts in

small lot sizes.

Disadvantages of machining centers:

·

These machines are more expensive compared to other

conventional machines.

·

Need highly skilled and trained labors to

operate these machines.

·

Needs software’s for DNC, Simulation and CAM

programming, which makes the cost higher to use these machines.

Features of CNC machining centers:

Usually the CNC machining centers are designed with many features

to reduce non productive time. Some of the features are:

1.

Automatic tool changer (ATC).

2.

Automatic work part positioned.

3.

Automatic pallet changer.

1. Automatic tool changer (ATC):

The Cutting tools are stored in the storage

unit called the “tool magazine” which is integrated with the machine tool and

named with the tool numbers. When a tool number is called by the tool number

the magazine rotates to the proper position and an automatic tool changer (ATC)

with the program control, exchanges the tool in the spindle for the tool in the

tool storage unit. The Capacities of tool magazine commonly range from 16 to 80

cutting tools. These Automatic tool changes save the manual tool changing and

the big save on the cycle time or the operation time.

2. Automatic work part positioned:

Automatic work part positioning acts as

rotary axis rotating the part and give access to the cutting to machine, many

horizontal and vertical machining centers have the capability to orient the

work part relative to the spindle. The table can be oriented at any angle about

a vertical axis to permit the cutting tool to access almost the entire surface

of the part in a single setup. These automatic work part positions are

programmed by the programmer. The positioning of the rotation is very important

the tool need to move to safety plane when there is a big rotation in the

rapid. With these features we can reduce the number of setups and save huge

time and gain increase in productivity.

3. Automatic pallet changer:

Recent modern Machining centers are equipped

with two (or more) separate pallets that can be changed using an automatic

pallet changer. While machining is performed with one pallet in position at the

machine, the other pallet is in a safe location out of the machine. The

operator can unload the finished part and then fixture the raw work part for

next cycle with the pallet outside the machine. Using these automatic pallet

changers the time of loading and unloading the part can be saved and the

machine will be loaded continuously. These featured machines are very helpful in

mass production activity.

Enjoy learning CNC Programming.